AMERICANS LOVE THEIR t-shirts. In fact, over 62 percent of Americans claim to currently own more than 10 t-shirts as part of their wardrobe.

This alone means that there are 1.5 billion t-shirts that have been printed and sold. These shirts, lined end to end would be enough to circle the globe over 34 times. The t-shirt is a way we promote our favorite brands, organizations, teams and just about anything else.

So’ who do we owe our thanks to?

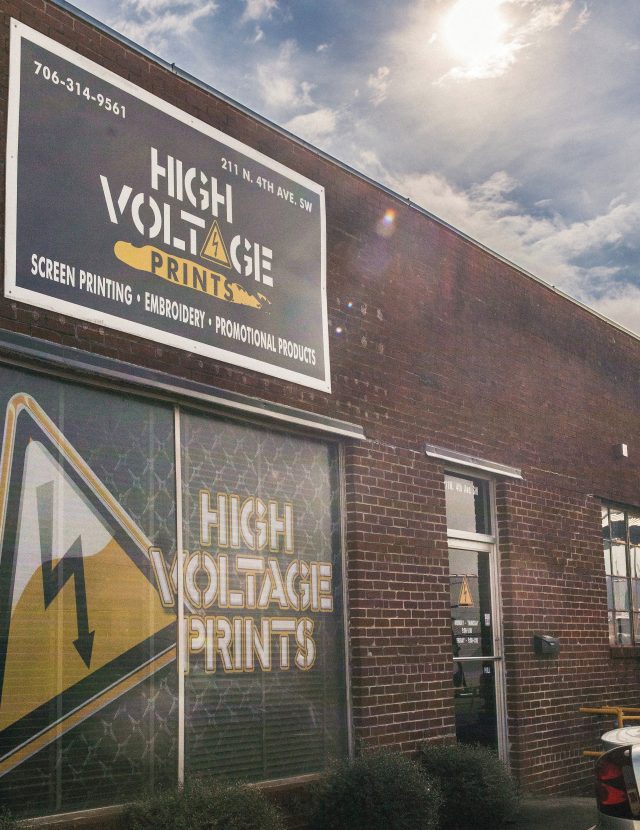

You can start with your local screen printer. For those around Rome, you might pay a visit to High Voltage Prints.

High Voltage Prints was founded in part by Jason Lansdell. This year marks Landsdell’s 20th year in screen printing, a passion he built from his first job as an entry-worker in a small print shop. Lansdell quickly fell in love with the craft, turning his fire for the industry and the skills he learned from every position he held, into his own business. But he wasn’t alone. When Lansdell opened shop on his own in Rome, which was no easy feat, he brought with him a team of skilled workers and experts of the trade.

“It was certainly tough, but my team already had a lot of experience. We’ve all been in the business for a long time, so it felt like coming in to do what we have always done well,” says Lansdell. “We certainly had to work hard to establish good business in Rome. It just takes a few customers to give you a chance and to see the kind of product a quality printer can deliver. Word certainly gets around.”

Lansdell and his fellow team members opened High Voltage Prints to combine the most up-to- date printing equipment and methods with the art of their in-house designers, delivering custom t-shirts and apparel to the customer. Aside from printing, Lansdell’s shop also offers embroidery services and a wide variety of specialty advertising products from key chains and pens to banners and signs. According to Lansdell, the key to success in the printing industry is simple.

“First it starts with great art. And second, delivering the job on time,” says Lansdell. However, after a simple walk-through of the High Voltage Prints workshop, one can see that the process between art and neatly pressed shirts in a box is far more complex.

When a customer has an idea for a quantity of shirts, hats or other apparel they would like to have designed and printed, the first stop is the High Voltage Workshop on North 4th Avenue in Rome, Ga. After a greeting from Jason, Alyson, or another member of the team, it is time for a consultation. According to Lansdell, it all begins with the design. “Some people come in knowing exactly what they want, bringing art files to simply hand off to the team,” says Lansdell. “Others come in not entirely sure of what they want and ask us to develop the art. Whichever way we have to go about the job, at the end of the day it is all about a quality product and a happy customer.”

The art for the product is digitally designed in-house. Lansdell relies on his team of artists, who eat and breathe graphic design, to develop art that will not only stand out, but exceed the expectations of the customer. This is where the magic happens. Once the design has been approved by the customer, it is now up to Lansdell and his shop-crew to exemplify the art of their trade using some of the finest tools on the market.

In the shop, one can hear the whirring of machines and view the screen printing tools that appear almost like a carousel of robotics. Each individual task has its station, from creating the screens to the drying station.

The first step in the shop is to create the screen that will be used in the printer. All of the artwork designed by the team is sent to a computer located within the shop that is connected to a device which writes the files digitally onto the screens made from synthetic threads, that can be used to manufacture thousands of prints. For a printer, having the ability to manufacture screens in house is not only a way to get the product to the consumer quicker, but a way to differentiate the shop from competition. At a normal professional print shop, it can take as long as 15 minutes to manufacture one screen. However, with Lansdell’s machine, this process takes less than two seconds. After this process is complete, the screens are taken to a bay where they are sprayed with water. Now they are ready to be used in the printer.

The printer is the heart of any print shop. The quality of the printer not only determines the speed at which a professional printer can deliver a product to the consumer, but it also determines the final quality of the product produced.

The printer is the heart of any print shop. The quality of the printer not only determines the speed at which a professional printer can deliver a product to the consumer, but it also determines the final quality of the product produced.

High Voltage Prints is happy to be a beta shop for what stands as the world’s fastest and one of the best quality printers available. The product itself resembles the skeleton of a merry-go-round, having arms containing the ink and screens to print on the shirts as they rotate around the machine.

This product, made by a company based out of Chicago called M & R, currently holds the world record for the fastest printer on the market, boasting an astounding 2600 shirts or printed materials per hour. Although High Voltage Prints doesn’t print at this speed, the overall quality produced by this machine gives the shop a true edge on the competition. From here, the shirts are taken off the machine by a member of the crew, and placed in the dryer.

The ink used for the shirts can only be dried at a high temperature; a professional dryer is used to complete the job. This dryer heats the shirt to precisely 325 degrees, the temperature needed to completely dry the ink, and is then delivered out of the back as a finished product.

In the end, Lansdell and his team hope to carry on their trade well into the future. And the future certainly holds a lot in store for High Voltage Prints. For Lansdell and his team, this is only the beginning of the journey. But for now, they will continue to design and print a quality product, and stand as leaders of their industry.