There are people who say you can’t buy happiness, but they probably haven’t bought a carton of mint chocolate chip ice cream and scraped the bottom after a long day.

Through thick and thin, ice cream has always been there for us. It’s a compliment to your favorite soda, a loyal attendee at every birthday party, a therapist after a breakup. For ages, ice cream has been the top selling dessert in the country next to cookies. Many of us have noticed that these two dessert powerhouses are known to be thrown together every now and then.

Origins of ice cream have been traced back as far as 2nd century B.C.

Where once it was a dessert for only the elite members of society, now everyone can enjoy the creamy, luscious goodness of a scoop of Moose Tracks. However, as time passed, as with most things, we began to cut a few corners and skimp on the ice cream recipe. Yes, you can still buy your specialty flavor from Ben and Jerry. Or, you can tell yourself that Haagen-Dazs is real, imported Danish ice cream (plot twist, the founder made up this word as a marketing ploy), but is this what ice cream is really meant to be?

The time has come to discover a new age of ice cream in a place where a small business, scooping up a new “super-premium” brand of flavors, hopes to let everyone get a taste of what this cold treat can do in the hands of skilled artisans.

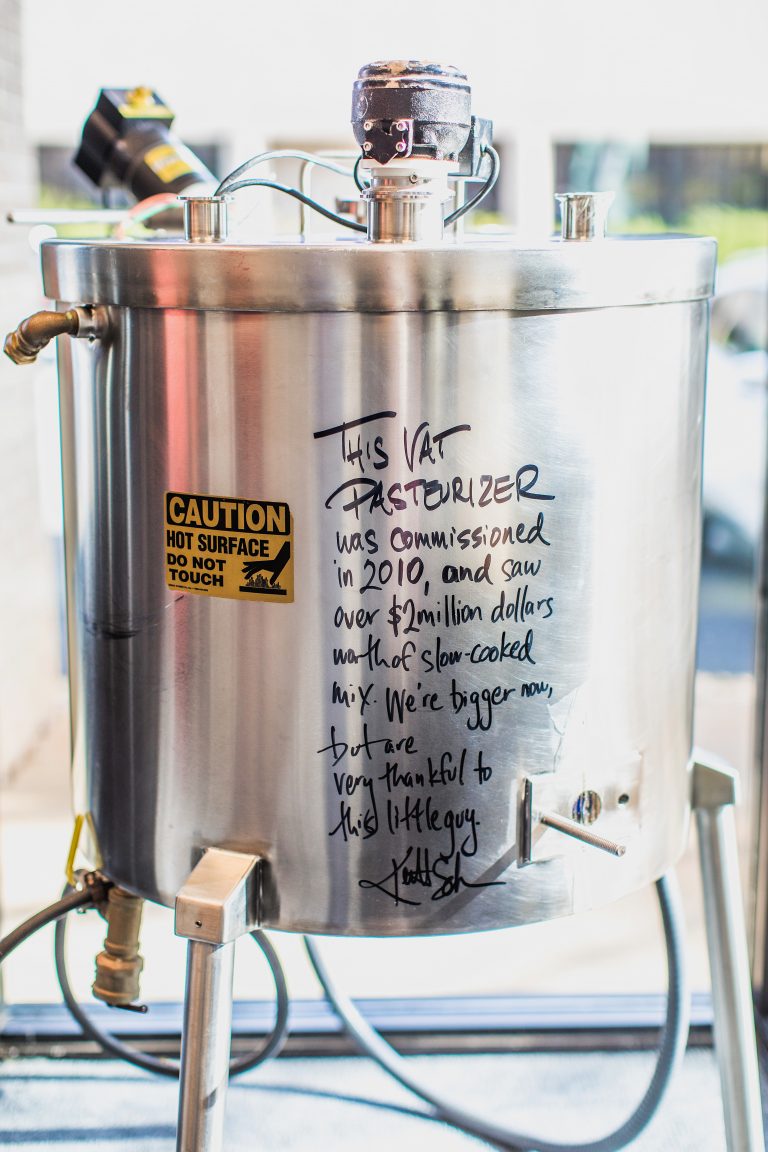

Just inside the small office front of their much larger ice cream manufacturing facility in Marietta, Georgia, lies the original pasteurizer that High Road founder Keith Schroeder used to make his first batches of gourmet ice cream. Though the contraption may seem out of place, looking more like a piece off of the Starship Enterprise than a simple pasteurizer, this is truly where High Road Craft Ice Cream was born.

Schroeder began work using this machine in the company’s first facility in Chamblee, Georgia, when the enterprise was taking its first steps producing gourmet, handmade ice cream.

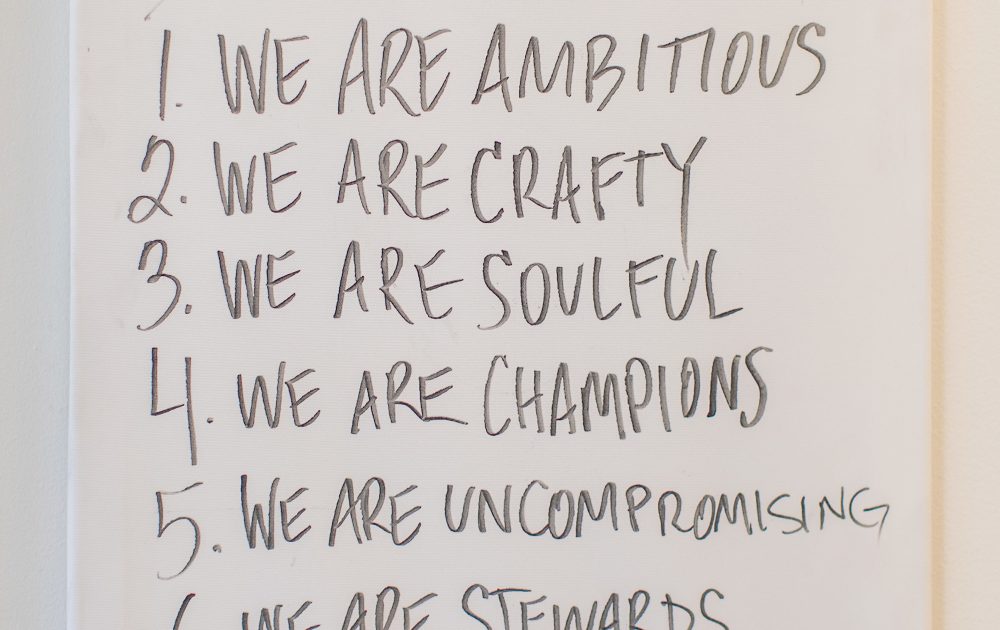

In 2010, High Road opened the door to its first facility with a simple premise of producing handmade, high quality-food service ice cream by chefs, and for chefs. But why is a small pasteurizer important in the first place? In a way, it represents the company’s founding belief. Schroeder knew that to truly take the high road, his ice cream would be made by not cutting corners.

As you make your way further back into the High Road complex, past the scribbled chalk boards and offices, you’ll soon step into the heart of Schroeder’s dream. When the company reached a demand for their product that their small facility couldn’t maintain, it was time for a move and a big step forward. They would also need to hire a few extra imaginative chefs with a real sweet-tooth. The money was raised to build a substantially larger facility in Marietta, Georgia, with brand new machines and a gigantic commercial kitchen that would allow the grow-ing team of culinary artists to begin fully taking advantage of High Road’s potential.

This is when Christian Rodriguez, one of High Road’s leading chefs, joined the cause. Rodriguez can attest to the uniqueness and the need for a company such as High Road, because as a chef in his former job, he was an early customer of the company.

“There was really a void in the industry for having super-premium quality ice cream in restaurants; it’s the last thing that chefs think about. As a chef, I’ve ordered for restaurants before where the main focus is meat, fish and center of the plate items, but nobody really remembers the ice cream which was a common problem. This is how I became a High Road customer,” Rodriguez explains. “Creating a super-premium brand where ice cream can now be the center of the plate as the desert is special. It can not only be the focal point, but maybe even the meal. Having that super luscious, super rich, made from scratch taste, all made in Atlanta has been our goal. That’s what is really putting us on the map.”

Here, Rodriguez stops to look back at a large window where inside busy hands are working in a beautiful new commercial kitchen, and he takes note of a smell. “What you smell now is poblano peppers and ancho chilies. We’re making a chile jam that will go over a chile pepper ice cream for tomorrow,” Rodriguez smiles. “We now can make the ice cream in massive amounts, hundreds and hundreds of gallons at a time!”

The process for making such a product is one that is a labor of love. The first stop is the “raw room”, where Rodriguez points out the thousands of pounds of raw ingredients being stored in a enormous cooler, waiting to be turned into a mix to make the ice cream.

In the room stands a liquefier, which serves as a giant blender, along with a scale to measure out the tested and proven recipes. Here is where High Road stores their shipments of milk and cream, which they receive 300 gallons of each at once. This shipment of milk and cream will only last the company about five days, but will (along with the other various ingredients) yield over 800 gallons of custom ice cream mix. Once various ingredients are weighed and mixed according to the unique formula pertinent to a particular batch, then the cream is added.

Next, Rodriguez points to a large pasteurizer, one that makes High Road’s first pasteurizer in comparison look like a Ford Model T parked next to the latest Mercedes Benz.

However, though they have upgraded, the company still uses a method of pasteurization called “kettle cooked vat pasteurization”, an old world method—French in origin—which according to Rodriguez is “the way chef’s in-tended for ice cream to be made.” This is but one of the elements that makes High Road such a rare company, using methods such as this pasteurization technique that has long since been compromised by the industry. This method is one of the elements that allows High Road to make a product high in butterfat, and rich in flavor, capturing the true essence of what handcrafted ice cream used to be.

Another unique aspect of High Road is their policy on inclusions, which simply put, is all the rest of the delicious ingredients that make up your favorite flavor besides the ice cream itself.

Whether it is a Fresh Mint Chip, Aztec Chocolate, or their signature (and my personal favorite) Bourbon Burnt Sugar, made with Kentucky bourbon and sorghum, High Road bakes, slices, grinds, and chops up locally sourced, premium ingredients to make their flavors. Be-cause of this, a lot of the ice cream produced is seasonal. “Last strawberry season we spent over 4 days just tipping strawberries to use,” laughs Rodriguez. “We make a lot [of the inclusions] by hand. We make everything from brownies, to chocolate chunk, to shortbread, to pralines, really anything that can be made in-house is produced here.”

All of these ingredients are then stored and refrigerated until they are ready to be included in the next batch of ice cream.

All in all, there is a precise science behind the making of ice cream. Ice cream artisans have to ensure they are following strict formulas, con-trolling the levels of steam during pasteurization, and dedicate the copious amounts of time needed to produce their final product. After the process is complete, the ice cream is then stored at a frigid -20 degrees, until it is ready to be shipped.

Just like Willy Wonka’s Chocolate Factory, which honestly isn’t such a bad comparison to the facilities at High Road, the facility selectively opens its doors to the general public and allows them to taste the latest batch of fresh ice cream. However, here you don’t have to have a golden ticket; you simply have to keep an eye on their Facebook page for their next “scoop shop” day.

The company values the feedback from the general public. So, they’ve actually built a small scoop shop onto the side of their facilities to be open on select days. However, if you can’t make it to a scoop day, you can find the BLVD Line of High Road Ice Cream in Whole Foods, one of the first major partners to take on High Road’s product.

For being a six-year-old company, one that started off simply as a college MBA project, High Road is expanding to reach the shelves of retailers across the country, to give everyone a chance to taste real ice cream. Looking forward, High Road has a goal of playing alongside such ice cream barons as Ben and Jerry, all the while maintaining those special elements that make their ice cream a truly unique culinary experience.

So, is it time for a cheat day on that New Year’s resolution diet? For the love of ice cream, and all things good in this world, have a scoop for us.

For ordering information call 678-701-7623 or find your flavor online at highroadcraft.com.